4.1. Thickness and bearing capacity design

The bearing capacity of a gravel road or forest road can be described as the maximum stress or pressure that road can sustain without failure of the road structure or subgrade material under the road. The maximum stress or pressure should be defined by the trucks that using the roads. In addition to road structures and their material properties the bearing capacity performance of gravel and forest roads is also controlled by road drainage, seasonal changes and maintenance practices. Poor or neglected maintenance operations can “destroy” good gravel or forest roads in just a few years.

The design principles of gravel roads can vary substantially between different countries and between public gravel roads and forest roads and between different road classes.

4.2. Design principles

Gravel roads

In gravel road road design the bearing capacity or road structure thickness is mainly defined by the subgrade soil type and quality. In Finland the layer thicknesses are defined by the estimated subgrade soil moduli value and the target moduli value is set by the importance class of the gravel road. This design does not take into account frost. Frost design principles are used only when building transition wedge structures.

In Sweden the gravel road layer thickness design is also based on the subgrade type, but in addition the local climate zones also have an effect on the total thickness. The wearing course and base course thickness is thinner in Sweden compared to Finland, but the Swedish total thickness is mainly thicker.

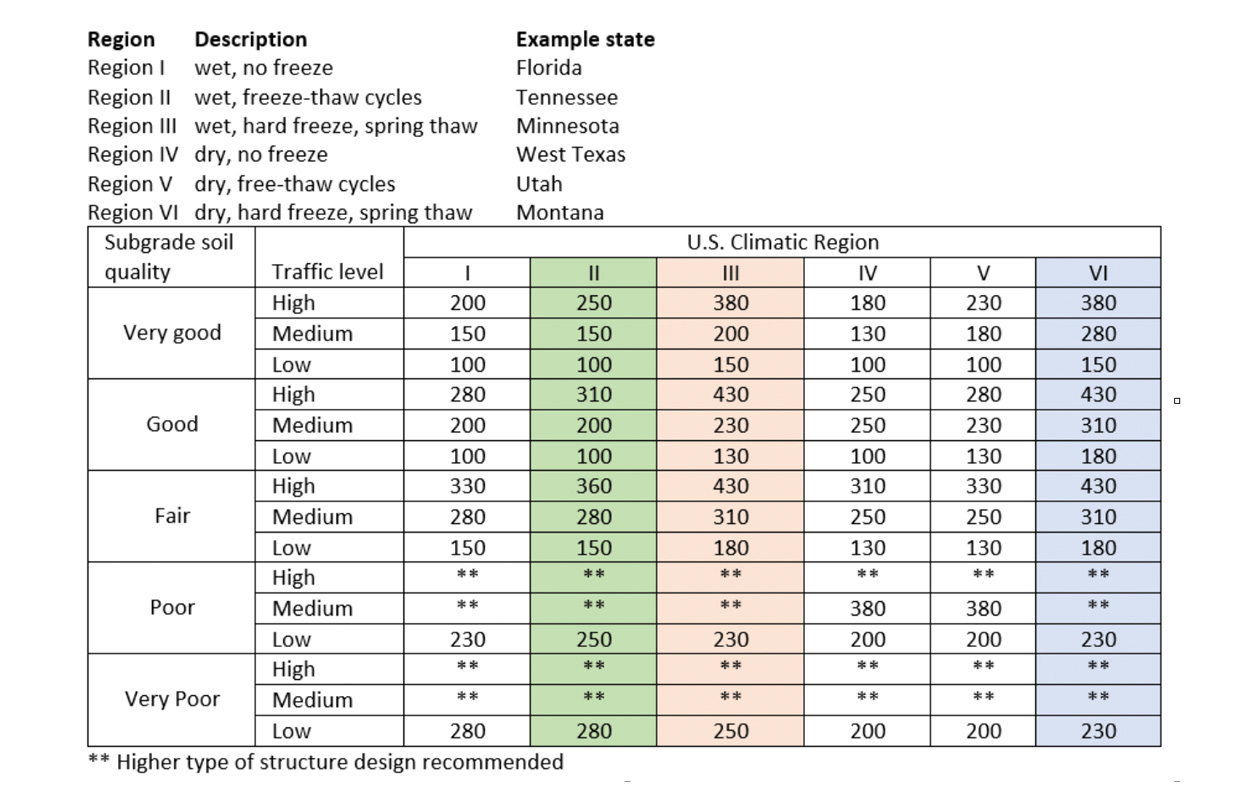

As a comparison of gravel road structure design principles in the ROADEX area, the following table presents the design table used in the USA. In the USA the gravel road structure mainly consists of a base course over the subgrade and a wearing course. This design system also has climatic regions and subgrade soil quality and in addition the traffic level has also a great effect on base course structure thickness. The traffic level refers to equivalent standard axles (ESAL) of 8 ton axle load, where a high traffic level is defined as 60.000-100.000 ESAL, medium is 30.000-60.000 ESAL and Low 10.000-30.000 ESAL. In addition, if detailed information of the subgrade and road aggregate quality is available, it is recommended that the AASHTO design method should be used.

Forest roads

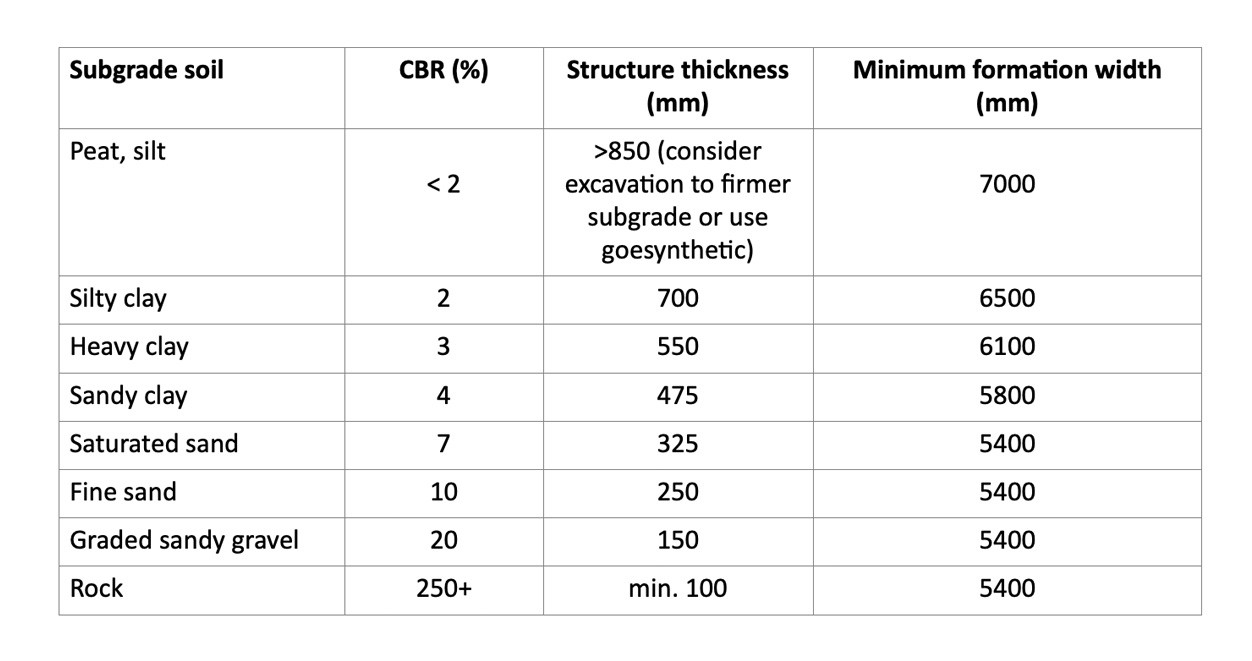

Forest road structure designs in ROADEX area are mainly based on design catalogues/tables where the main factor defining the structure thickness is subgrade soil type. In Scotland the subgrade is defined by its CBR (California Bearing Ratio) value. In addition, the subgrade soil type also defines the foundation (formation) width which is correspondingly wider the weaker the subgrade soil is.

In Finland the design is also based on four forest road structure classes with different the target bearing capacity (MN/m2) during the spring thaw or during the summer. Structure classes I and II with target bearing capacity classes 80 MN/m2 and 60 MN/m2 can be used all year around while in classes III and IV heavy traffic is not allowed in weaker subgrade classes D-F during the spring thaw.

Comparing all the above structural design tables of gravel and forest roads reveals that they all seem to be in line, even though their design concepts are different. Knowing however the great variations in axle weights and total weights across countries it cannot be confirmed if all tables meet all the requirements of heavier trucks. Based on the ROADEX tests on gravel and forest roads in partner areas ROADEX has recommended the following classification based on the bearing capacity measured on the top of wearing course.

In addition to the table the following issues should be kept in mind when designing or strengthening gravel roads.

- If bedrock is close to road surface, this might lead to underdesigning structures and Mode 1 rutting

- If the road is resting on peat this might lead to overdesigning the structures

- If drainage is poor this might lead to overdesign. The much cheaper is to improve the drainage.